Introduction

In an increasingly global and complex market, supply chain disruptions are becoming more frequent and costly. Natural disasters, geopolitical tensions, demand surges, and logistical delays can halt operations and create ripple effects that impact production, delivery, and customer satisfaction. Traditional supply chain management tools often react to problems after they occur, leaving businesses scrambling to mitigate losses.

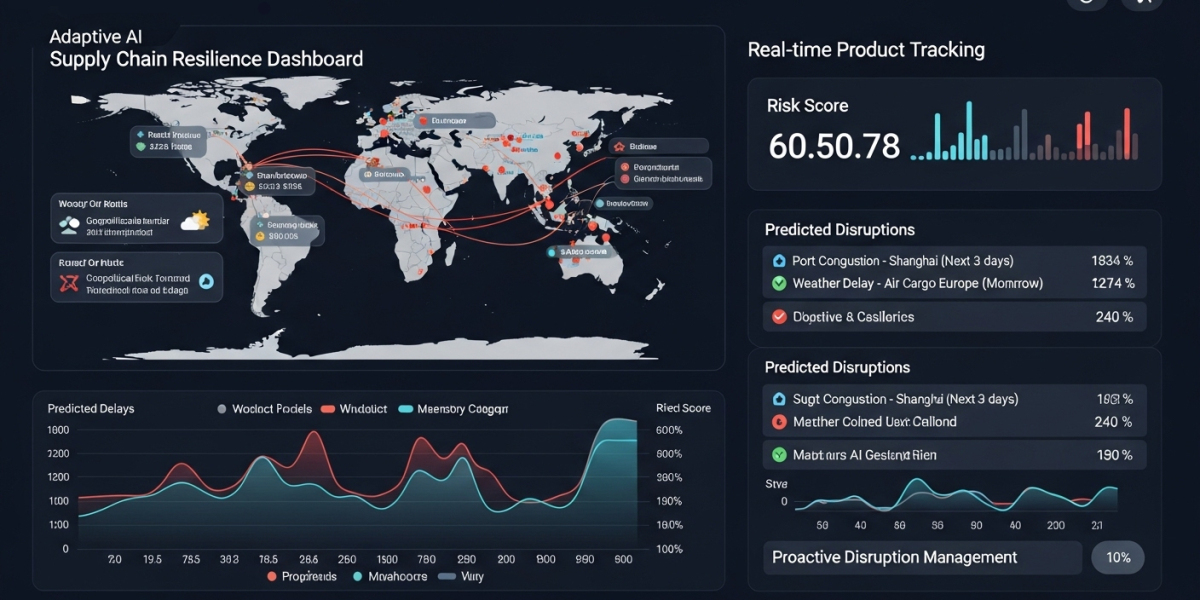

Adaptive AI is changing this dynamic by predicting disruptions before they occur and enabling organizations to take proactive measures. By analyzing vast amounts of real-time data across suppliers, logistics networks, and market trends, adaptive AI allows companies to anticipate challenges, optimize operations, and maintain continuity. Organizations leveraging adaptive AI development services are now transforming supply chain resilience from reactive to predictive.

What Is Adaptive AI in Supply Chain Management?

Adaptive AI refers to artificial intelligence systems that continuously learn from real-world data and dynamically adjust their models to evolving conditions. Unlike traditional AI, which often relies on static algorithms, adaptive AI evolves over time, refining predictions and recommendations as new data becomes available.

In supply chain management, adaptive AI:

Forecasts demand shifts and potential inventory shortages.

Monitors supplier performance and identifies early signs of delays.

Predicts transportation and logistics bottlenecks.

Recommends contingency plans, such as alternative suppliers or route adjustments.

Through adaptive AI solution development, companies gain a self-learning system that not only identifies potential problems but also prescribes solutions before disruptions escalate.

How Adaptive AI Solves Supply Chain Challenges

1. Predictive Inventory Management

Adaptive AI analyzes historical demand patterns, real-time sales, and market trends to anticipate inventory needs. This predictive capability helps businesses:

Reduce stockouts and overstock situations.

Optimize warehouse storage and distribution planning.

Adjust procurement strategies proactively to align with demand fluctuations.

By predicting inventory requirements, adaptive AI ensures that resources are available when needed, minimizing disruption risks and reducing costs associated with emergency procurement or lost sales.

2. Supplier Risk Monitoring

Suppliers are a critical link in any supply chain, and delays or quality issues can have cascading effects. Adaptive AI continuously monitors supplier performance indicators, such as delivery timeliness, production capacity, and financial stability.

If early warning signs of risk emerge, the system can recommend alternative suppliers, adjust order quantities, or reroute deliveries to maintain operational continuity. This proactive approach ensures that businesses are not caught off guard by sudden disruptions.

3. Dynamic Route Optimization

Transportation delays often contribute to supply chain disruptions. Adaptive AI leverages real-time traffic, weather data, and shipping schedules to optimize delivery routes.

It can reroute shipments to avoid potential delays.

Adjust delivery schedules dynamically based on changing conditions.

Integrate predictive logistics into broader supply chain planning for more reliable fulfillment.

This continuous route optimization reduces transit time, prevents bottlenecks, and ensures timely deliveries to customers.

4. Risk Forecasting and Scenario Planning

Adaptive AI enables companies to simulate potential disruption scenarios using predictive analytics. By evaluating multiple “what-if” scenarios, organizations can:

Assess the impact of natural disasters, strikes, or geopolitical events on supply chains.

Identify vulnerable nodes in the network.

Develop contingency plans to maintain operational continuity.

This proactive approach transforms supply chain management from reactive problem-solving to strategic risk mitigation.

Key Features of Adaptive AI in Supply Chains

Adaptive AI’s effectiveness comes from several key capabilities:

Self-Learning Models: Continuously refine predictions based on new data.

Real-Time Analytics: Monitor live data streams from suppliers, logistics, and market trends.

Predictive Forecasting: Anticipate disruptions before they occur.

Dynamic Optimization: Adjust orders, routes, and resource allocation automatically.

Cross-System Integration: Connect ERP, CRM, warehouse management, and transportation systems for holistic insights.

Decision Support: Provide actionable recommendations to managers for strategic interventions.

These features allow supply chains to become smarter, faster, and more resilient.

Benefits of Adaptive AI in Supply Chain Management

Implementing adaptive AI delivers tangible results:

Reduced Stockouts and Overstocks: Predictive analytics ensures inventory aligns with real demand.

Improved Supplier Reliability: Early risk detection prevents delays and quality issues.

Faster Delivery Times: Dynamic routing and logistics optimization improve customer satisfaction.

Lower Operational Costs: Proactive planning reduces emergency procurement and expedited shipping expenses.

Enhanced Resilience: Organizations can quickly adapt to unexpected disruptions without halting operations.

The cumulative effect is a supply chain that operates with greater efficiency, reliability, and foresight.

Implementation Strategy

To integrate adaptive AI into supply chain management successfully, organizations should follow these steps:

Identify High-Impact Areas: Focus on critical processes prone to disruption, such as procurement, logistics, or inventory management.

Data Preparation: Consolidate and clean data from suppliers, transportation systems, and market sources.

Collaborate with Experts: Partner with an adaptive AI development company to design models tailored to organizational needs.

Pilot and Test: Begin with a controlled deployment to validate predictions and recommendations.

Monitor and Iterate: Continuously evaluate performance, retrain AI models, and refine strategies.

Integrate Human Oversight: Maintain transparency and decision-making control while leveraging AI insights.

This structured approach ensures adaptive AI development services deliver measurable improvements in supply chain resilience.

Industries Benefiting from Adaptive AI in Supply Chains

Adaptive AI is transforming supply chain management across multiple sectors:

Retail: Anticipates consumer demand and optimizes inventory replenishment.

Manufacturing: Ensures raw materials and components are available for uninterrupted production.

Healthcare: Maintains critical medical supplies and reduces risk of stockouts.

Logistics: Optimizes delivery routes, scheduling, and capacity planning.

Food and Beverage: Predicts demand spikes and minimizes waste from perishable inventory.

Across industries, adaptive AI enables organizations to stay ahead of disruptions and maintain seamless operations.

Future Trends

Adaptive AI will continue to evolve supply chain management in the following ways:

End-to-End Visibility: Real-time insights across the entire supply chain network.

Autonomous Decision-Making: AI systems that automatically adjust procurement, production, and logistics based on predictions.

Predictive Digital Twins: Virtual models that simulate disruptions and test responses in advance.

Human-AI Collaboration: Managers use AI recommendations to make faster, smarter decisions without replacing human expertise.

Sustainability Optimization: AI predicts and reduces environmental impact by optimizing routes, inventory, and supplier choices.

Organizations that invest in adaptive AI solution development now will build supply chains that are more agile, resilient, and competitive.

Conclusion

Supply chain disruptions are inevitable in today’s complex business environment, but adaptive AI is making them manageable. By predicting risks, automating responses, and optimizing workflows, adaptive AI transforms supply chains from reactive networks into proactive, intelligent systems.

Through adaptive AI development services, businesses can anticipate challenges, maintain continuity, reduce costs, and deliver better outcomes for customers.